Revolutionizing Wind Turbine Inspections with Drone Technology

As wind energy continues to grow in importance, maintaining wind turbines efficiently is crucial to ensure optimal performance and longevity.

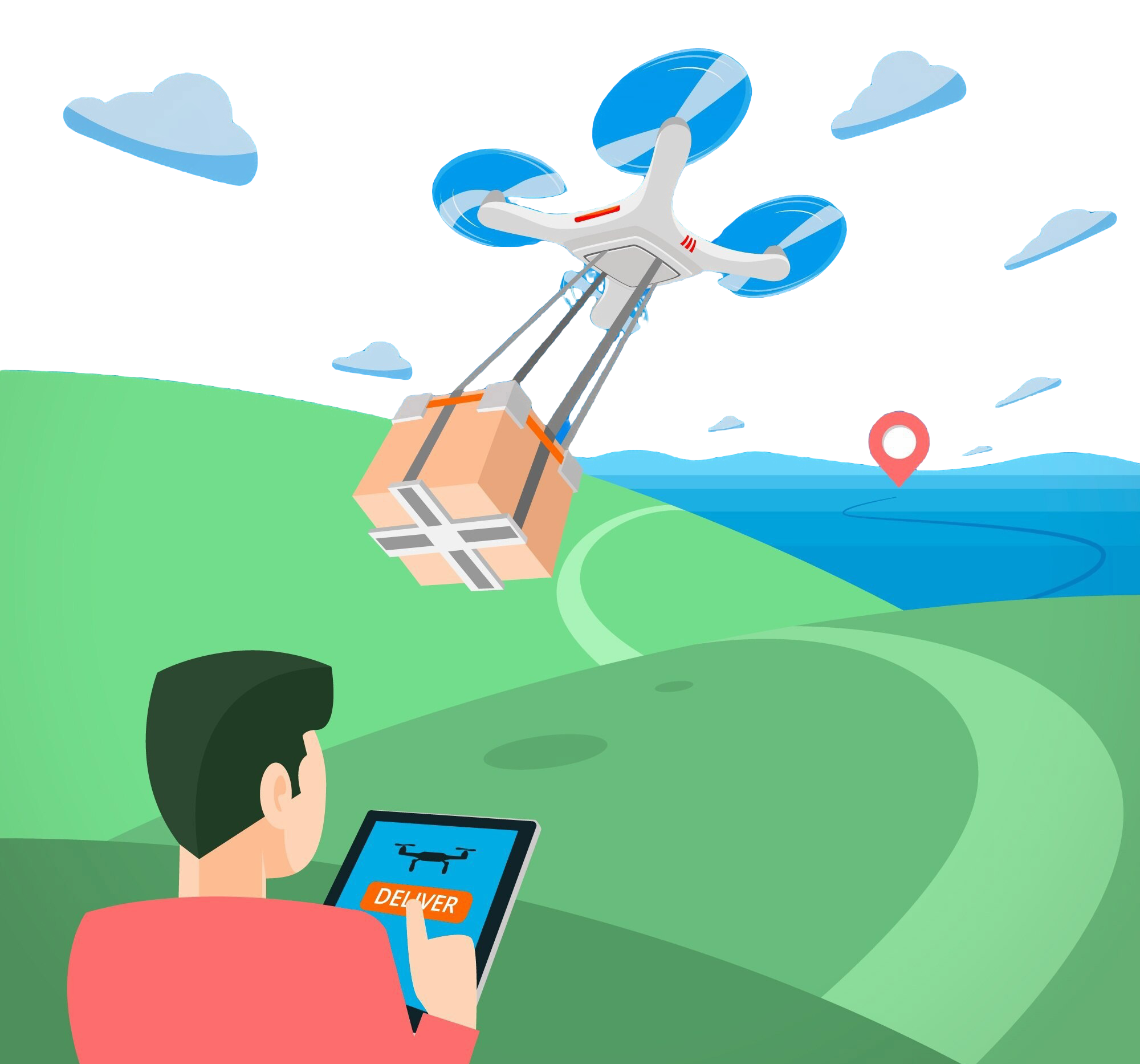

At Atom Aviation, we harness the power of drones to make wind turbine inspections safer, faster, and more cost-effective. By combining advanced imaging technology with the agility of drones, we offer precise, non-intrusive surveys that eliminate many of the challenges associated with traditional inspection methods.

Challenges in Traditional Wind Turbine Inspections

Conventional wind turbine inspections often involve complex setups, including cranes or rope-access teams, and require turbines to be shut down for long periods. In offshore wind farms, access difficulties and weather conditions can lead to costly delays. The risks to human inspectors, particularly in high-altitude or remote locations, make routine maintenance inspections both time-consuming and hazardous.

In just a fraction of the time needed for manual inspections, drones can capture detailed images of turbine blades, towers, and nacelles, covering large wind farms in record time.

By eliminating the need for heavy equipment and reducing downtime, our services cut inspection costs dramatically, allowing operators to focus resources on maintenance and repair.

With drones, inspectors remain safely on the ground, while the drone navigates even the tallest turbines and hard-to-reach locations, removing personnel from harm’s way.

Critical Applications of Drone Surveys for Wind Turbines:

Blade Integrity Checks: Wind turbine blades are constantly exposed to harsh conditions, leading to cracks, erosion, and other damage. Our drone inspections detect these defects early, ensuring repairs are carried out before failures occur.

Thermal Imaging: By using infrared cameras, we can detect overheating components that are invisible to the naked eye. This proactive approach helps prevent unexpected downtime.

Post-Storm Assessments: After severe weather events, rapid drone deployment allows for a thorough examination of structural damage, enabling immediate action to minimize energy losses.